Harnessing the Potential of SLS Technology in Modern Art Supplies, Product Design, and 3D Printing

In the rapidly evolving world of creative industries and manufacturing, SLS technology (Selective Laser Sintering) has emerged as a groundbreaking innovation that is reshaping how artists, designers, and manufacturers approach their crafts. From revolutionizing art supplies to redefining *product design* and enabling high-precision 3D printing, SLS technology offers unparalleled capabilities that foster creativity, efficiency, and precision.

Understanding SLS Technology: The Foundation of Modern Additive Manufacturing

At its core, SLS technology is a powerful additive manufacturing process that uses a high-powered laser to sinter powdered materials layer by layer, creating complex and durable objects directly from digital models. Unlike traditional manufacturing methods, which often require molds or subtractive processes, SLS allows for the seamless production of intricate and customized parts with minimal waste.

Key aspects of SLS technology include:

- Material versatility: Capable of working with various powders such as nylon, polystyrene, metals, and ceramics.

- Complex geometries: Ability to produce intricate designs impossible with conventional methods.

- Rapid prototyping: Significantly reducing time-to-market for new products.

- Robust and durable parts: Resulting objects have excellent mechanical properties suitable for functional applications.

The Role of SLS Technology in Enhancing Art Supplies

Artistic innovation thrives on the availability of versatile, precise, and customizable tools and materials. SLS technology plays a transformative role in the development of innovative art supplies, empowering artists to push creative boundaries.

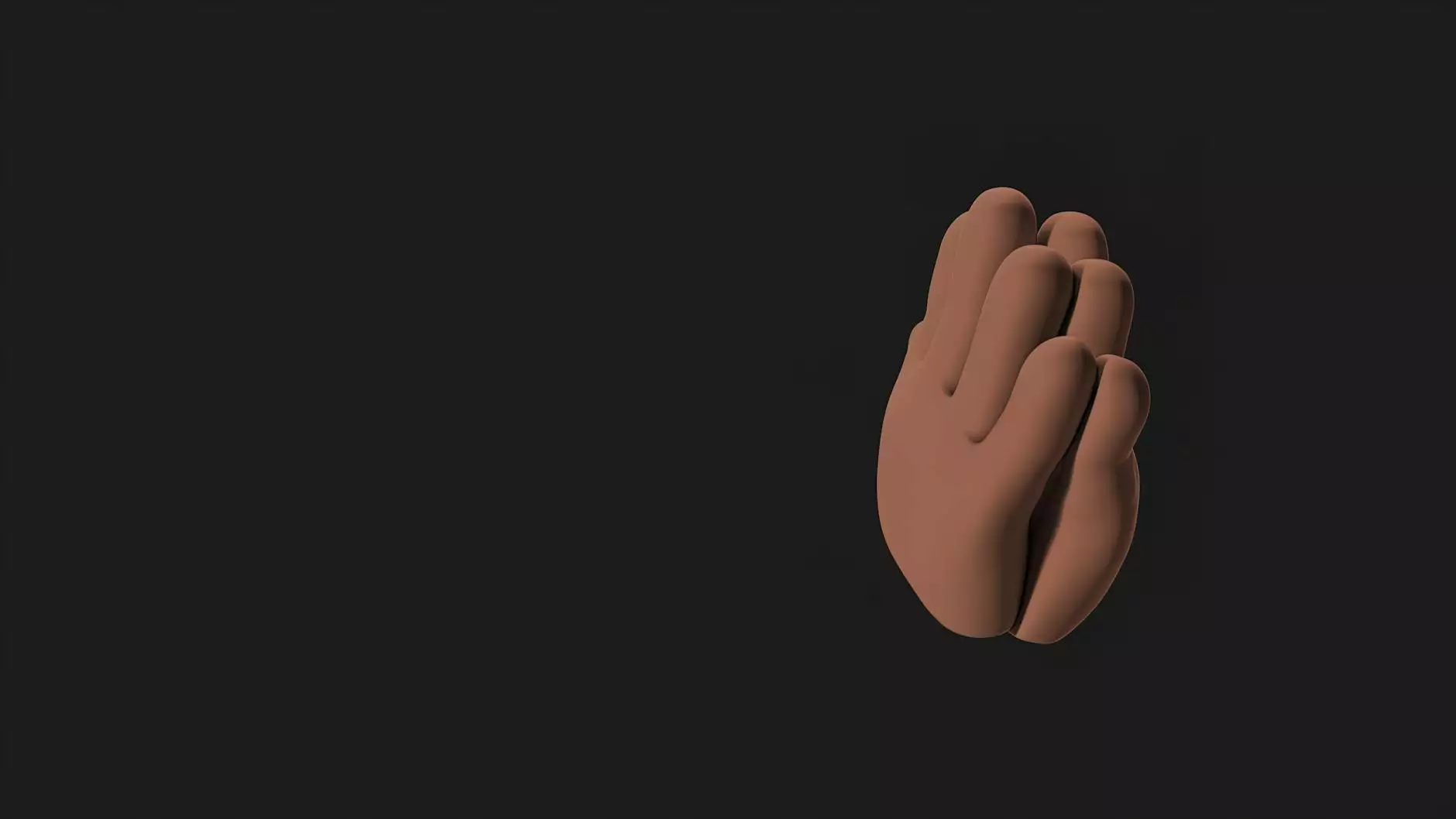

Creating Custom Art Tools and Accessories with SLS technology

Using SLS technology, artisans and suppliers can produce complex, ergonomic, and bespoke art tools tailored to individual artist needs. From personalized palette knives to detailed sculpture tools, the flexibility of SLS enables rapid prototyping and production of high-quality art hardware with precision fits and finishes.

Innovative Material Usage for Artistic Expression

The expanding library of powders suitable for SLS technology means artists can experiment with a variety of textures and finishes. For example, nylon powders can be combined with additional materials to create textured surfaces or translucent finishes, enriching artistic experimentation.

Benefits in Artistic Manufacturing

- Customization: Artists can create unique, one-of-a-kind art tools or decorative elements.

- Speed: Rapid iteration of prototypes and models accelerates the artistic process.

- Durability and precision: The resulting tools and art objects are long-lasting, with intricate details preserved.

The Impact of SLS Technology on Product Design and Development

In the realm of product design, SLS technology provides designers and engineers with an unparalleled platform for innovation. It bridges the gap between creative concepts and functional prototypes, enabling fast, cost-effective, and precise production of complex geometries.

Streamlining the Product Development Lifecycle

Using SLS technology, companies can rapidly iterate product prototypes without the need for expensive molds or tooling. This flexibility accelerates the design process, allowing for multiple revisions and functional testing, ultimately leading to faster commercialization.

Design Freedom Unlocked by SLS technology

The ability of SLS to produce complex internal structures, lightweight yet durable components, and geometries with undercuts provides an edge in designing innovative products. Manufacturers in industries such as automotive, aerospace, healthcare, and consumer electronics benefit from the high precision and customization potential of SLS.

Cost-Effectiveness and Sustainability

Compared to traditional manufacturing, SLS technology produces less waste, uses fewer materials, and minimizes the need for assembly. The additive nature means that components can be optimized for weight and strength, reducing material costs and environmental impact.

The Revolution of SLS Technology in 3D Printing

3D printing has become synonymous with innovation, and SLS technology stands as one of its most influential methods. Its ability to produce high-quality, functional, and complex parts positions it as a cornerstone of modern manufacturing and creative endeavors.

High-Precision, Functional 3D Printing

Unlike other 3D printing methods that may offer limited material choices or lower resolution, SLS provides exceptionally detailed and mechanically stable components. This makes it ideal for functional prototypes, final parts, and customized small-batch production.

Expanding Material Horizons in 3D Printing

The evolution of powder materials compatible with SLS now includes metal alloys, biocompatible plastics, and ceramics. These broaden the scope of applications, allowing industries to manufacture medical implants, aerospace components, or artistic sculptures with intricate designs and durable properties.

Economic and Environmental Advantages

- Reduced waste: As an additive process, SLS minimizes excess material usage.

- On-demand production: Lower inventory costs by printing parts as needed.

- Energy efficiency: Process optimization leads to lower energy consumption compared to subtractive manufacturing.

Future Trends: Leveraging SLS Technology for Innovation

The continuous advancement in SLS technology is opening new horizons across multiple sectors. Here are some future trends that will shape its role in art, design, and manufacturing:

Integration with Digital Design Ecosystems

Enhanced software integration for more complex, parametric designs and AI-driven customization allows for personalized art pieces and custom product lines developed at scale.

Development of New Materials

Research into biodegradable plastics, metal composites, and multi-material powders aims to expand the creative and functional capacity of SLS, pushing the boundaries of what can be achieved with additive manufacturing.

Automation and Smart Manufacturing

The combination of SLS technology with industry 4.0 principles will enable fully automated production lines, improving consistency, reducing costs, and expanding accessibility for small and medium-sized enterprises.

Conclusion: Embracing SLS Technology for a Creative and Efficient Future

From empowering artists with innovative art supplies to accelerating product development and revolutionizing 3D printing, SLS technology stands at the forefront of manufacturing and creative innovation. Its versatility, precision, and cost-effectiveness make it an indispensable tool for those aiming to push the limits of what is possible.

Businesses and creatives who harness the power of SLS technology will be better positioned to lead in their industries, offering customized, intricate, and high-quality products that meet the demanding expectations of modern markets. As technology advances, its role will only become more prominent, encouraging a future full of limitless possibilities and unprecedented innovation.

Visit arti90.com to explore how our offerings in art supplies, product design, and 3D printing leverage SLS technology to turn your creative visions into reality. Embrace the future now—unlock your creative potential with SLS technology.